Account

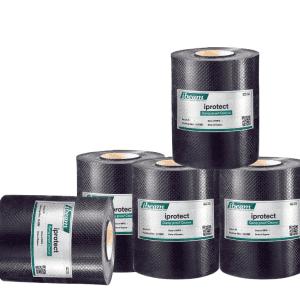

Pipe wrapping tape

14.70 USD

Pipe wrapping tape is used for protection of pipes in various industrial and construction applications. it plays vital role in the infrastructure, marine and construction industry. Especially to safeguard water network pipes from alkaline and acidic components from soil.

Or

At Manufacturer Price

Share this Pipe wrapping tape product.

Pipe wrapping tape Features, Benefits & Technical Details

Pipe wrapping tape, or pipe repair tape, is a specialised type of self-adhesive tape used for various purposes related to pipes, pipelines, and plumbing systems.

The anti-corrosive PVC pipe wrapping tape system is designed to safeguard pipelines and repair pipes from corrosion and environmental damage. Made from high-performance polyethene or PVC backing with a specialised adhesive layer, this tape creates a durable, watertight barrier around pipes, ensuring long-term protection and extending the pipeline’s lifespan.

Advantages of pipe wrapping tape:

- Corrosion protection.

- Leak Repair & Insulation.

- Excellent adhesion.

- Easy to install.

- Excellent durability

Area of application:

- Pipeline industry.

- The material can be applied cold or self-adhesive.

- Submarine application.

- Drinking & sewerage water pipeline

Available sizes: 1.5 mm thickness, width 100, 150, 200, 225, 250 mm x 10, 15, 20M roll.

Available brands: Duwrap, Bitutape, Oxiwrap PVC, Corrowrap, Iwrap

Pipe wrapping tape FAQs

What is Pipe Wrapping Tape and its main applications?

Pipe wrapping tape, also known as pipe repair tape, is a specialized type of self-adhesive tape used for various purposes related to pipes, pipelines, and plumbing systems. ibeam supplies anti-corrosive PVC pipe wrapping tape systems designed to safeguard pipelines and repair pipes from corrosion and environmental damage. Made from high-performance polyethylene or PVC backing with a specialized adhesive layer, this tape creates a durable, watertight barrier around pipes, ensuring long-term protection and extending the pipeline’s lifespan. Primary applications include pipeline industry protection, cold applied and self-adhesive installation systems, submarine applications, and drinking & sewerage water pipeline protection. The tape is designed for both above-ground and underground pipeline systems requiring corrosion protection and leak prevention.

What technical specifications and performance characteristics does ibeam supply?

ibeam directly procures pipe wrapping tapes from certified manufacturers with comprehensive specifications:

- Thickness: 1.5mm thickness providing robust protection and mechanical strength for demanding pipeline applications

- Width Options: Available in 100mm, 150mm, 200mm, 225mm, and 250mm widths accommodating various pipe diameters and coverage requirements

- Roll Lengths: 10m, 15m, and 20m roll lengths for different project scales and application convenience

- PVC/Polyethylene Backing: High-performance backing materials providing excellent durability, chemical resistance, and weather protection

- Specialized Adhesive: Advanced adhesive formulation ensuring superior bonding to various pipe materials and substrates

- Corrosion Protection: Outstanding anti-corrosive properties protecting against salt water, acids, alkalis, and environmental contaminants

- Watertight Barrier: Excellent moisture resistance creating effective barrier against water infiltration and vapor transmission

- Temperature Resistance: Wide temperature range performance suitable for various climatic conditions and installation environments

- UV Resistance: Enhanced UV stability for extended outdoor exposure and long-term performance reliability

- Easy Installation: Cold applied and self-adhesive properties enabling straightforward installation without special equipment

In which countries and regions does ibeam supply Pipe Wrapping Tapes?

ibeam has established a strong presence across key strategic markets as a reliable bulk supplier of pipe wrapping tapes:

- GCC Countries: Extensive supply to UAE, Saudi Arabia, Kuwait, Qatar, and Oman for oil & gas pipelines, water infrastructure, and industrial facility applications

- Top African Markets: Active distribution network serving Nigeria, Egypt, South Africa, Kenya, Ghana, Tanzania, Uganda, Morocco, Ethiopia, and Angola with diverse pipeline protection and infrastructure maintenance requirements

- Regional Expertise: Deep understanding of local pipeline practices, environmental conditions, and corrosion protection requirements across GCC and African markets

- Project Experience: Successfully supplied to oil & gas projects, water treatment facilities, marine applications, industrial pipelines, and infrastructure development projects

- Quality Sourcing: Direct procurement from certified manufacturers ensuring consistent quality, performance standards, and competitive pricing

- Strategic Positioning: UAE-based operations with efficient logistics network enabling large-scale project supply and timely delivery across all markets

- Climate Adaptation: Products specifically tested for extreme temperature conditions, high humidity, salt water exposure, and aggressive environmental conditions typical in regional applications

- Technical Expertise: Local engineering support and application guidance adapted to regional pipeline standards and environmental challenges

What are the key advantages of ibeam's Pipe Wrapping Tapes?

Pipe Wrapping Tape FAQs – ibeam.ae

1. What is Pipe Wrapping Tape and its main applications?

Pipe wrapping tape, also known as pipe repair tape, is a specialized type of self-adhesive tape used for various purposes related to pipes, pipelines, and plumbing systems. ibeam supplies anti-corrosive PVC pipe wrapping tape systems designed to safeguard pipelines and repair pipes from corrosion and environmental damage. Made from high-performance polyethylene or PVC backing with a specialized adhesive layer, this tape creates a durable, watertight barrier around pipes, ensuring long-term protection and extending the pipeline’s lifespan. Primary applications include pipeline industry protection, cold applied and self-adhesive installation systems, submarine applications, and drinking & sewerage water pipeline protection. The tape is designed for both above-ground and underground pipeline systems requiring corrosion protection and leak prevention.

2. What technical specifications and performance characteristics does ibeam supply?

ibeam directly procures pipe wrapping tapes from certified manufacturers with comprehensive specifications:

- Thickness: 1.5mm thickness providing robust protection and mechanical strength for demanding pipeline applications

- Width Options: Available in 100mm, 150mm, 200mm, 225mm, and 250mm widths accommodating various pipe diameters and coverage requirements

- Roll Lengths: 10m, 15m, and 20m roll lengths for different project scales and application convenience

- PVC/Polyethylene Backing: High-performance backing materials providing excellent durability, chemical resistance, and weather protection

- Specialized Adhesive: Advanced adhesive formulation ensuring superior bonding to various pipe materials and substrates

- Corrosion Protection: Outstanding anti-corrosive properties protecting against salt water, acids, alkalis, and environmental contaminants

- Watertight Barrier: Excellent moisture resistance creating effective barrier against water infiltration and vapor transmission

- Temperature Resistance: Wide temperature range performance suitable for various climatic conditions and installation environments

- UV Resistance: Enhanced UV stability for extended outdoor exposure and long-term performance reliability

- Easy Installation: Cold applied and self-adhesive properties enabling straightforward installation without special equipment

3. In which countries and regions does ibeam supply Pipe Wrapping Tapes?

ibeam has established a strong presence across key strategic markets as a reliable bulk supplier of pipe wrapping tapes:

- GCC Countries: Extensive supply to UAE, Saudi Arabia, Kuwait, Qatar, and Oman for oil & gas pipelines, water infrastructure, and industrial facility applications

- Top African Markets: Active distribution network serving Nigeria, Egypt, South Africa, Kenya, Ghana, Tanzania, Uganda, Morocco, Ethiopia, and Angola with diverse pipeline protection and infrastructure maintenance requirements

- Regional Expertise: Deep understanding of local pipeline practices, environmental conditions, and corrosion protection requirements across GCC and African markets

- Project Experience: Successfully supplied to oil & gas projects, water treatment facilities, marine applications, industrial pipelines, and infrastructure development projects

- Quality Sourcing: Direct procurement from certified manufacturers ensuring consistent quality, performance standards, and competitive pricing

- Strategic Positioning: UAE-based operations with efficient logistics network enabling large-scale project supply and timely delivery across all markets

- Climate Adaptation: Products specifically tested for extreme temperature conditions, high humidity, salt water exposure, and aggressive environmental conditions typical in regional applications

- Technical Expertise: Local engineering support and application guidance adapted to regional pipeline standards and environmental challenges

4. What are the key advantages of ibeam’s Pipe Wrapping Tapes?

ibeam supplies pipe wrapping tapes offering superior performance characteristics and operational benefits:

- Superior Corrosion Protection: Outstanding anti-corrosive properties protecting pipelines from environmental damage and extending service life

- Effective Leak Repair and Insulation: Excellent sealing capabilities for leak repair applications and thermal insulation properties

- Excellent Adhesion: Superior bonding to various pipe materials including steel, plastic, concrete, and coated surfaces

- Easy Installation: Simple cold applied and self-adhesive installation process requiring no special tools or heating equipment

- Exceptional Durability: Long-term performance with resistance to weathering, UV exposure, chemical attack, and mechanical damage

- Versatile Application: Suitable for pipeline industry, submarine applications, drinking water systems, and sewerage infrastructure

- Cost-Effective Protection: Economical alternative to expensive coating systems while providing comparable or superior protection

- Wide Temperature Range: Effective performance across varied temperature conditions from sub-zero to high temperature environments

- Chemical Resistance: Outstanding resistance to acids, alkalis, salts, oils, and various industrial chemicals

- Maintenance Reduction: Significant reduction in pipeline maintenance requirements and associated operational costs

What packaging and shipping options does ibeam provide for Pipe Wrapping Tapes?

ibeam offers comprehensive packaging and shipping solutions for pipe wrapping tape products:

- Standard Roll Sizes: Multiple width options (100-250mm) and length options (10-20m) with 1.5mm thickness for various application requirements

- Bulk Options: Multiple roll configurations and pallet loads for large-scale pipeline projects and maintenance operations

- Export Packaging: Moisture-proof packaging with proper sealing for international shipping and extended storage requirements

- Custom Solutions: Tailored cutting services, custom widths, and specific roll lengths for unique pipeline applications

- Shipping Costs: All freight charges calculated at actual rates based on destination, quantity, and selected transportation method

- Freight Options: Sea freight for bulk orders, air freight for urgent requirements, and land transport for regional GCC deliveries

- Container Loading: Optimized loading configurations maximizing container utilization and reducing per-unit shipping costs for bulk orders

- Documentation: Complete shipping documentation including technical specifications, safety certificates, and application guidelines

- Delivery Terms: FOB, CIF, and DAP terms available depending on customer requirements and destination logistics capabilities

- Storage Guidelines: Proper handling instructions and storage requirements to maintain tape quality during transport and field storage

What export procedures and documentation does ibeam handle for Pipe Wrapping Tapes?

ibeam manages comprehensive export procedures for pipeline protection products across international markets:

- Export Licensing: Proper export permits and industrial material handling licenses for all destination countries and regulatory requirements

- Documentation Requirements: Commercial invoices, packing lists, certificates of origin, and Material Safety Data Sheets (MSDS) for customs clearance

- Regulatory Compliance: Adherence to international pipeline protection standards including ASTM, API, and local industry regulations

- Quality Certificates: Certificates of analysis, performance testing reports, and third-party verification documents when required by authorities

- Customs Procedures: Professional customs clearance support and documentation preparation for smooth border processing and reduced delays

- Transit Times: 7-14 days for GCC countries, 15-25 days for African markets, and 20-30 days for Asian destinations via sea freight

- Tracking Services: Complete shipment tracking with regular status updates throughout the delivery process from dispatch to final destination

- Insurance Coverage: Comprehensive marine insurance options available for high-value shipments and specialized pipeline materials

- Regulatory Support: Assistance with destination country import permits, industrial material certifications, and local compliance procedures

- Technical Documentation: Complete application guidelines, installation procedures, and performance specifications in multiple languages

What are ibeam's payment terms and credit policies for Pipe Wrapping Tapes?

ibeam maintains clear and consistent payment policies for all pipeline protection material transactions:

- First Transaction Policy: No credit terms available for new customers; payment required in advance or against delivery documentation

- Payment Methods: Bank transfers, letters of credit, and documentary collections accepted in USD and AED currencies only

- Credit Availability: Credit terms only available against Post-Dated Cheques (PDCs) and proper legal documentation with financial guarantees

- Credit Assessment: Comprehensive financial evaluation including trade license verification, bank statements, and legal entity registration documents

- Required Documents: Audited financial statements, bank references, trade references, and legal entity documentation for credit approval

- Credit Limits: Established based on financial capacity assessment, trading history evaluation, and market presence verification

- Payment Security: All credit transactions secured against legal documents, bank guarantees, and guaranteed payment instruments

- Currency Options: International transactions processed in USD; local UAE business conducted in AED with proper invoicing and documentation

- Collection Procedures: Professional debt recovery procedures with legal enforcement capabilities across key export markets

- Project Terms: Special payment arrangements available for large pipeline projects with verified financing and government backing

What are the available brands and quality standards for Pipe Wrapping Tapes?

ibeam supplies pipe wrapping tapes from leading international and regional manufacturers with comprehensive quality assurance:

- Available Brands: Leading international pipeline protection manufacturers, specialized tape producers, and certified adhesive technology companies with proven track records

- Quality Standards: ISO 9001:2015 certified manufacturing processes ensuring consistent product quality and performance characteristics

- International Compliance: Products manufactured to ASTM standards, API specifications, and other international pipeline protection requirements

- Performance Testing: Comprehensive adhesion testing, corrosion resistance verification, temperature cycling, and durability assessment

- Material Standards: Virgin PVC and polyethylene formulations meeting international polymer standards for pipeline applications

- Technical Support: Expert application guidance, installation support, and troubleshooting assistance across all supplied brands

- Environmental Compliance: UV resistance, chemical stability, and environmental durability meeting international performance guidelines

- Industry Standards: Compliance with oil & gas industry specifications, water utility standards, and marine application requirements

- Customization Options: Custom formulations, specialized adhesives, and tailored solutions available for specific application requirements

- Regional Adaptation: Products specifically tested and certified for Middle East and African environmental conditions and pipeline practices

What safety requirements and application procedures apply to Pipe Wrapping Tapes?

ibeam emphasizes comprehensive safety protocols and proper application procedures for pipe wrapping tape installation:

- Surface Preparation: Proper cleaning of pipe surfaces, removal of rust, oil, and contaminants for optimal adhesion

- Application Conditions: Appropriate temperature and humidity conditions for installation ensuring proper adhesive activation

- Installation Technique: Proper wrapping methods with appropriate overlap, tension control, and air bubble elimination

- Personal Protection: Standard protective equipment during handling and application including gloves and eye protection

- Storage Requirements: Proper storage conditions protecting from moisture, extreme temperatures, and UV exposure

- Quality Control: Regular inspection of application quality, adhesion verification, and performance monitoring

- Environmental Considerations: Proper disposal of waste materials and adherence to environmental regulations

- Safety Documentation: Complete Material Safety Data Sheets (MSDS) and handling guidelines for safe use

- Installation Training: Proper training requirements for application personnel ensuring optimal installation quality

- Performance Verification: Regular monitoring of tape performance, adhesion integrity, and protection effectiveness

What technical support and application guidance does ibeam provide?

ibeam offers comprehensive technical support services for optimal pipe wrapping tape performance and application:

- Application Consultation: Expert guidance on tape selection, width determination, and thickness requirements for specific pipeline applications

- Installation Support: Technical assistance with application procedures, surface preparation, and installation techniques

- Performance Optimization: Professional guidance on environmental considerations, temperature effects, and long-term performance factors

- Quality Assurance: Regular quality monitoring, batch testing, and performance verification to ensure consistent tape effectiveness

- Training Services: Technical training programs for installers covering proper handling, application methods, and quality control procedures

- Documentation Support: Complete technical data sheets, installation guidelines, and maintenance specifications in multiple languages

- Field Support: On-site technical assistance available for large pipeline projects and complex protection applications

- Problem Solving: Professional troubleshooting support for adhesion challenges, environmental issues, and performance optimization

- Custom Solutions: Engineering support for specialized applications including marine environments, extreme temperatures, and chemical exposure

- Regional Expertise: Local technical knowledge adapted to Middle East and African pipeline practices, environmental conditions, and regulatory requirements

Why Choose ibeam’s Pipe Wrapping Tape?

- Superior corrosion protection for industrial & utility pipelines.

- Waterproof, UV-resistant & durable for long-term use.

- Easy-to-apply with strong adhesion for all surfaces.

- Available in multiple widths & thicknesses.

- Fast delivery across UAE, Middle East and African countries with competitive pricing.

Please Contact us for bulk orders or Get custom quote.

Why ibeam?

Complete Construction Care

Your one stop solution for all your construction needs.

Precised Products

Tailored made solutions for your requirements

Time Sensitive Solutions

Prompt, Precise and Guaranteed timely delivery, every time.

Dedicated Support

Personalized assistance and expert guidance every step.

Pipe wrapping tape Supplier in UAE

The most trusted and reliable Pipe wrapping tape supplier in the UAE, delivering to all locations at manufacturer prices.

Pipe wrapping tape Supplier in Dubai

We are a wholesale supplier of Pipe wrapping tape in Dubai at manufacturer price, available for delivery across Deira, Bur Dubai, Karama, Satwa, Al Quoz, Jumeirah, Marina, JLT, Business Bay, Al Barsha, Discovery Gardens, Dubai Silicon Oasis, International City, Mirdif, Al Warqa, Nad Al Sheba.

Pipe wrapping tape Supplier in Abu Dhabi

Supplying premium quality Pipe wrapping tape in Abu Dhabi at manufacturer price, available for delivery across Mussafah, Khalifa City, Al Reem Island, Al Maryah Island, Al Raha, Yas Island, Saadiyat Island, Baniyas, Al Shahama, Al Mafraq, Al Wathba, Al Falah, Madinat Zayed, Al Bateen.

Pipe wrapping tape Supplier in Sharjah

We are a wholesale supplier of Pipe wrapping tape in Sharjah at manufacturer price, available for delivery across Al Nahda, Al Qasimia, Al Khan, Muwailih, Rolla, Al Majaz, Al Taawun, University City, Al Nasseriya, Al Yarmook, Al Jubail, Industrial Area, Al Layyah, Al Rahmaniya.

Pipe wrapping tape Supplier in Ajman

Supplying premium quality Pipe wrapping tape in Ajman at manufacturer price, available for delivery across Al Nuaimiya, Al Rashidiya, Al Jurf, Musherief, Al Mowaihat, Al Rawda, Helio, Al Zahra, Al Hamidiya, Al Nakhil, Al Manama.

Pipe wrapping tape Supplier in Ras Al Khaimah

We are a wholesale supplier of Pipe wrapping tape in Ras Al Khaimah at manufacturer price, available for delivery across Al Nakheel, Al Dhait, Al Rams, Al Jazeera, Julphar, Seih Al Uraibi, Al Mamourah, Khuzam, Al Hamra, Mina Al Arab, Digdaga.

Pipe wrapping tape Supplier in Fujairah

Supplying premium quality Pipe wrapping tape in Fujairah at manufacturer price, available for delivery across Al Faseel, Sakamkam, Dibba, Al Qurayyah, Mirbah, Qidfa, Masafi, Al Hayl, Madhab, Ghub, Al Bidya.

Pipe wrapping tape Supplier in Umm Al Quwain

We are a wholesale supplier of Pipe wrapping tape in Umm Al Quwain at manufacturer price, available for delivery across Al Salamah, Al Ramlah, Al Haditha, Al Riqqah, Falaj Al Mualla, Al Abraq, Al Dar Al Baida, Al Khor, Al Humrah.

Pipe wrapping tape Supplier in Al Ain

Supplying premium quality Pipe wrapping tape in Al Ain at manufacturer price, available for delivery across Al Hili, Al Jimi, Al Bateen, Al Towayya, Al Foah, Zakher, Al Maqam, Al Yahar, Al Ain Industrial Area, Sweihan, Mezyad, Remah.

Pipe wrapping tape Supplier in Khor Fakkan

We are a wholesale supplier of Pipe wrapping tape in Khor Fakkan at manufacturer price, available for delivery across Al Haray, Luluyah, Al Badia, Al Zubarah, Al Ghail, Al Miqat, Shis, Nahwa, Al Suhub Rest Area.

Pipe wrapping tape Supplier in Dibba Al Fujairah

Supplying premium quality Pipe wrapping tape in Dibba Al Fujairah at manufacturer price, available for delivery across Dibba Al Hisn, Dibba Al Baya (Oman), Al Aqah, Dadna, Mirbah, Rol Dhadnah, Wadi Sidr, Awhala, Tawyeen.

Pipe wrapping tape Supplier in Saudi Arabia

The most trusted and reliable Pipe wrapping tape supplier in the Saudi Arabia, delivering to all locations at manufacturer prices.

Pipe wrapping tape Supplier in Riyadh

We are a wholesale supplier of Pipe wrapping tape in Riyadh at manufacturer price, available for delivery across Al Malaz, Al Olaya, Al Murabba, Al Batha, Al Yasmin, Al Rawdah, Al Munsiyah, Al Khaleej, Al Wurud, Al Safa, Al Uraija, Diriyah, Al Kharj, Al Shifa, Al Maather

Pipe wrapping tape Supplier in Jeddah

Supplying premium quality Pipe wrapping tape in Jeddah at manufacturer price, available for delivery across Al Balad, Al Hamra, Al Rawda, Al Rehab, Al Safa, Al Salamah, Al Aziziyah, Al Marwah, Al Naseem, Al Bawadi, Al Faisaliyah, Obhur, Rabigh, Thuwal, Asfan.

Pipe wrapping tape Supplier in Mecca

We are a wholesale supplier of Pipe wrapping tape in Mecca at manufacturer price, available for delivery across Al Aziziyah, Al Awali, Al Shoqiyah, Al Nuzha, Al Taif, Al Jumum, Bahrah, Al Kuday, Al Rusaifah, Mina, Muzdalifah, Arafat, Al Hindawiyah, Al Shara’i, Al Zahra.

Pipe wrapping tape Supplier in Medina

Supplying premium quality Pipe wrapping tape in Medina at manufacturer price, available for delivery across Quba, Al Haram, Al Khalidiyyah, Al Aqiq, Al Ula, Yanbu, Al Awali, Al Madinah Al Munawwarah, Al Hanakiyah, Al Mahd, Al Qiblatain, Al Dirah, Badr, Al Qassim.

Pipe wrapping tape Supplier in Dammam

We are a wholesale supplier of Pipe wrapping tape in Dammam at manufacturer price, available for delivery across Al Faisaliah, Al Mazruiyah, Al Jalawiyah, Al Shatea, Al Aziziyah, Al Khalij, Al Muhammadiyah, Al Hamra, Al Raka, Al Nuzha, Al Awjam, Saihat, Tarout, Qatif.

Pipe wrapping tape Supplier in Khobar

Supplying premium quality Pipe wrapping tape in Khobar at manufacturer price, available for delivery across Al Aqrabiyah, Al Ulaya, Al Khuzama, Al Thuqbah, Al Nahda, Al Qadisiyah, Al Rakah, Al Rawabi, Al Aziziyah, Al Jawharah, Al Hizam, Half Moon Bay, Dhahran.

Pipe wrapping tape Supplier in Dhahran

We are a wholesale supplier of Pipe wrapping tape in Dhahran at manufacturer price, available for delivery across King Fahd University City, Al Qusour, Al Dana, Al Rowdha, Al Jamiah, Al Maha, Al Sheraa, Aramco Compound, Al Khalidiya, Al Mazaya, Al Firdaws, Al Mutlaq.

Pipe wrapping tape Supplier in Jubail

Supplying premium quality Pipe wrapping tape in Jubail at manufacturer price, available for delivery across Fanateer, Al Huwailat, Al Balad, Al Nakheel, Al Jalmudah, Al Rowdha, Al Andalous, Al Safa, Al Bahar, Industrial City, Ras Tanura, Qatif, Safwa, Al Khafji.

Pipe wrapping tape Supplier in Al Hasa

We are a wholesale supplier of Pipe wrapping tape in Al Hasa at manufacturer price, available for delivery across Al Hofuf, Al Mubarraz, Al Uqair, Al Taraf, Al Omran, Al Gournah, Al Jarn, Al Hufair, Al Jisha, Al Batha, Haradh, Al Khalidiyah, Al Turaif, Al Mughaisilah.

Pipe wrapping tape Supplier in Hail

Supplying premium quality Pipe wrapping tape in Hail at manufacturer price, available for delivery across Al Barzan, Al Quds, Al Salam, Al Nafal, Al Oqilat, Baqqa, Al Ghazalah, Al Shinan, Qina, Al Hujrah, Al Jubbah, Al Musaylimah, Al Arous, Al Uqdah.

Pipe wrapping tape Supplier in Qatar

The most trusted and reliable Pipe wrapping tape supplier in the Qatar, delivering to all locations at manufacturer prices.

Pipe wrapping tape Supplier in Doha

We are a wholesale supplier of Pipe wrapping tape in Doha at manufacturer price, available for delivery across Al Sadd, West Bay, The Pearl, Lusail, Al Waab, Al Rayyan, Madinat Khalifa, Al Hilal, Najma, Al Muntazah, Old Airport, Al Thumama, Al Duhail, Abu Hamour, Ain Khaled.

Pipe wrapping tape Supplier in Al Rayyan

Supplying premium quality Pipe wrapping tape in Al Rayyan at manufacturer price, available for delivery across Al Wajba, Al Gharrafa, Education City, Al Shafi, Al Themaid, Muaither, Al Sailiya, Izghawa, Al Luqta, Baaya, Rawdat Egdaim, Umm Al Afaei, Al Kaaban, Al Jemailiya.

Pipe wrapping tape Supplier in Al Wakrah

We are a wholesale supplier of Pipe wrapping tape in Al Wakrah at manufacturer price, available for delivery across Al Wukair, Mesaieed, Barwa Village, Ras Abu Fontas, Umm Al Houl, Al Mashaf, Wadi Aba Seleel, Ezdan Oasis, Al Jabal, Umm Al Seneem, Al Kharrara, Al Afjah.

Pipe wrapping tape Supplier in Umm Salal

Supplying premium quality Pipe wrapping tape in Umm Salal at manufacturer price, available for delivery across Umm Salal Ali, Umm Salal Mohammed, Izghawa, Al Kheesa, Al Mazrouah, Al Froosh, Al Daayen, Wadi Lusail, Abu Nakhla, Al Naemiya, Umm Garn, Umm Ebairiya.

Pipe wrapping tape Supplier in Al Khor

We are a wholesale supplier of Pipe wrapping tape in Al Khor at manufacturer price, available for delivery across Al Thakhira, Ras Laffan, Al Dhakira, Simaisma, Al Qarma, Al Jeryan, Al Jassasiya, Al Ghariyah, Al Zubarah, Umm Qarn, Al Jumail, Al Duhailiyat.

Pipe wrapping tape Supplier in Al Daayen

Supplying premium quality Pipe wrapping tape in Al Daayen at manufacturer price, available for delivery across Lusail, Wadi Lusail, Rawdat Al Hamama, Umm Qarn, Al Sakhama, Al Ebb, Al Kharaitiyat, Jeryan Jenaihat, Al Tarfa, Al Kaaban, Umm Qarn Al Jadidah.

Pipe wrapping tape Supplier in Mesaieed

We are a wholesale supplier of Pipe wrapping tape in Mesaieed at manufacturer price, available for delivery across Sealine Beach, Al Wakrah, Birkat Al Awamer, Umm Al Houl, Al Kharrara, Al Udeid, Al Mashaf South, Al Matar, Al Aamriya, Barwa City.

Pipe wrapping tape Supplier in Dukhan

Supplying premium quality Pipe wrapping tape in Dukhan at manufacturer price, available for delivery across Shahaniya, Al Nasraniya, Al Utouriya, Umm Bab, Al Jamiliyah, Abu Samra, Rawdat Rashid, Al Rafaa, Zekreet, Al Khurayb, Ras Abrouq.

Pipe wrapping tape Supplier in Al Shahaniya

We are a wholesale supplier of Pipe wrapping tape in Al Shahaniya at manufacturer price, available for delivery across Al Nasraniya, Al Utouriya, Al Khurayb, Al Aamriya, Rawdat Al Faras, Dukhan Highway, Umm Bab, Al Jemailiya, Ras Laffan Road, Umm Al Afaei

Pipe wrapping tape Supplier in Simaisma

Supplying premium quality Pipe wrapping tape in Simaisma at manufacturer price, available for delivery across Al Daayen, Al Khor, Al Thakhira, Lusail North, Umm Salal, Al Sakhama, Al Ghuwariyah, Jeryan Nejaima, Rawdat Al Hamama, Al Ebb.

Pipe wrapping tape Supplier in Oman

The most trusted and reliable Pipe wrapping tape supplier in the Oman, delivering to all locations at manufacturer prices.

Pipe wrapping tape Supplier in Muscat

We are a wholesale supplier of Pipe wrapping tape in Muscat at manufacturer price, available for delivery across Ruwi, Qurum, Al Khuwair, Seeb, Mutrah, Wadi Kabir, Al Ghubra, Madinat Al Sultan Qaboos, Azaiba, Al Hail, Ghala, Amerat, Al Maabilah, Al Bustan, Wadi Adai.

Pipe wrapping tape Supplier in Salalah

Supplying premium quality Pipe wrapping tape in Salalah at manufacturer price, available for delivery across Al Saada, Al Dahariz, Al Haffa, Al Wadi, New Salalah, Awqad, Ittin, Al Hisn, Taqah, Raysut, Dhareez, Mirbat, Sadah.

Pipe wrapping tape Supplier in Sohar

We are a wholesale supplier of Pipe wrapping tape in Sohar at manufacturer price, available for delivery across Falaj Al Qabail, Al Hambar, Al Batinah, Al Multaqa, Sallan, Al Khuwair South, Liwa, Shinas, Al Aqar, Majaz, Al Awabi

Pipe wrapping tape Supplier in Nizwa

Supplying premium quality Pipe wrapping tape in Nizwa at manufacturer price, available for delivery across Firq, Birkat Al Mouz, Bahla, Tanuf, Jabal Akhdar, Manah, Izki, Al Hamra, Misfat Al Abriyeen, Wadi Tanuf.

Pipe wrapping tape Supplier in Sur

We are a wholesale supplier of Pipe wrapping tape in Sur at manufacturer price, available for delivery across Al Ayjah, Ras Al Hadd, Tiwi, Qurayat, Al Kamil, Jalan Bani Bu Ali, Wadi Shab, Wadi Tiwi, Dhabab.

Pipe wrapping tape Supplier in Barka

Supplying premium quality Pipe wrapping tape in Barka at manufacturer price, available for delivery across Al Musanaah, Sawadi, Nakhal, Suwaiq, Wadi Al Maawil, Batinah Coast, Al Rumais, Al Hail North, Al Abyad.

Pipe wrapping tape Supplier in Ibri

We are a wholesale supplier of Pipe wrapping tape in Ibri at manufacturer price, available for delivery across Yanqul, Dhank, Hamra Al Duru, Al Buraimi, Wadi Al Ayn, Mahdha, Mazyad, Dhank Al Gharbia.

Pipe wrapping tape Supplier in Rustaq

Supplying premium quality Pipe wrapping tape in Rustaq at manufacturer price, available for delivery across Al Hazm, Al Awabi, Nakhal, Wadi Bani Khalid, Wadi Bani Auf, Al Qabil, Misfat, Ain Al Thawarah.

Pipe wrapping tape Supplier in Bahla

We are a wholesale supplier of Pipe wrapping tape in Bahla at manufacturer price, available for delivery across Al Hamra, Jabal Akhdar, Nizwa, Adam, Tanuf, Manah, Firq, Izki.

Pipe wrapping tape Supplier in Al Buraimi

Supplying premium quality Pipe wrapping tape in Al Buraimi at manufacturer price, available for delivery across Mahdha, Al Ain (UAE border), Hili Industrial Area, Sanaiya, Al Khadra, Wadi Al Jizi, Mazyad.

Pipe wrapping tape Supplier in Kuwait

The most trusted and reliable Pipe wrapping tape supplier in the Kuwait, delivering to all locations at manufacturer prices.

Pipe wrapping tape Supplier in Kuwait City

We are a wholesale supplier of Pipe wrapping tape in Kuwait City at manufacturer price, available for delivery across Salmiya, Hawally, Shuwaikh, Dasman, Mirqab, Bneid Al Qar, Sharq, Jabriya, Qibla, Kaifan, Surra, Mansouriya, Shaab, Abdullah Al-Salem.

Pipe wrapping tape Supplier in Salmiya

Supplying premium quality Pipe wrapping tape in Salmiya at manufacturer price, available for delivery across Rumaithiya, Salwa, Bayan, Mishref, Jabriya, Hawally, Shaab, Al Bidaa, Ras Salmiya, Salmiya Industrial Area

Pipe wrapping tape Supplier in Hawally

We are a wholesale supplier of Pipe wrapping tape in Hawally at manufacturer price, available for delivery across abriya, Salmiya, Bayan, Maidan Hawally, Rawda, Surra, Qadsiya, Nugra, Dasma

Pipe wrapping tape Supplier in Farwaniya

Supplying premium quality Pipe wrapping tape in Farwaniya at manufacturer price, available for delivery across Khaitan, Jleeb Al-Shuyoukh, Dajeej, Rehab, Abdullah Al-Mubarak, Omariya, Rabiya, Al Rai, Ardhiya.

Pipe wrapping tape Supplier in Ahmadi

We are a wholesale supplier of Pipe wrapping tape in Ahmadi at manufacturer price, available for delivery across Fahaheel, Mangaf, Mahboula, Abu Halifa, Egaila, Hadiya, Riqqa, Sabahiya, Wafra, Jaber Al-Ali.

Pipe wrapping tape Supplier in Jahra

Supplying premium quality Pipe wrapping tape in Jahra at manufacturer price, available for delivery across Sulaibiya, Saad Al-Abdullah, Naseem, Oyoun, Taima, Al Qasr, Naeem, Amghara Industrial Area, Mutlaa.

Pipe wrapping tape Supplier in Fahaheel

We are a wholesale supplier of Pipe wrapping tape in Fahaheel at manufacturer price, available for delivery across Mangaf, Abu Halifa, Mahboula, Egaila, Riqqa, Hadiya, Ahmadi, Fintas, Jaber Al-Ali.

Pipe wrapping tape Supplier in Mishref

Supplying premium quality Pipe wrapping tape in Mishref at manufacturer price, available for delivery across Bayan, Salam, Zahra, South Surra, Jabriya, Rumaithiya, Hiteen, Shuhada

Pipe wrapping tape Supplier in Jabriya

We are a wholesale supplier of Pipe wrapping tape in Jabriya at manufacturer price, available for delivery across Hawally, Salmiya, Mishref, Bayan, Rumaithiya, Zahra, Surra, Rawda.

Pipe wrapping tape Supplier in Mangaf

Supplying premium quality Pipe wrapping tape in Mangaf at manufacturer price, available for delivery across Abu Halifa, Fahaheel, Mahboula, Egaila, Riqqa, Hadiya, Sabahiya.

Pipe wrapping tape Supplier in African Countries

The most trusted and reliable Pipe wrapping tape supplier in the African Countries, delivering to all locations at manufacturer prices.

Pipe wrapping tape Supplier in Nigeria

We are a wholesale supplier of Pipe wrapping tape in Nigeria at manufacturer price, available for delivery across Lagos, Abuja, Kano, Ibadan, Port Harcourt, Benin City, Jos, Enugu, Kaduna, Aba.

Pipe wrapping tape Supplier in Egypt

Supplying premium quality Pipe wrapping tape in Egypt at manufacturer price, available for delivery across Cairo, Alexandria, Giza, Shubra El Kheima, Port Said, Suez, Luxor, Aswan, Tanta, Mansoura

Pipe wrapping tape Supplier in South Africa

We are a wholesale supplier of Pipe wrapping tape in South Africa at manufacturer price, available for delivery across Johannesburg, Cape Town, Durban, Pretoria, Port Elizabeth, Bloemfontein, East London, Kimberley, Polokwane, Nelspruit.

Pipe wrapping tape Supplier in Ethiopia

Supplying premium quality Pipe wrapping tape in Ethiopia at manufacturer price, available for delivery across Addis Ababa, Mekelle, Gondar, Adama, Bahir Dar, Dire Dawa, Hawassa, Dessie, Jimma, Shashamane.

Pipe wrapping tape Supplier in Kenya

We are a wholesale supplier of Pipe wrapping tape in Kenya at manufacturer price, available for delivery across Nairobi, Mombasa, Kisumu, Nakuru, Eldoret, Thika, Malindi, Nyeri, Machakos, Naivasha.

Pipe wrapping tape Supplier in Ghana

Supplying premium quality Pipe wrapping tape in Ghana at manufacturer price, available for delivery across Accra, Kumasi, Tamale, Sekondi-Takoradi, Tema, Cape Coast, Koforidua, Sunyani, Ho, Wa.

Pipe wrapping tape Supplier in Tanzania

We are a wholesale supplier of Pipe wrapping tape in Tanzania at manufacturer price, available for delivery across Dar es Salaam, Dodoma, Arusha, Mwanza, Mbeya, Tanga, Morogoro, Moshi, Tabora, Kigoma.

Pipe wrapping tape Supplier in Uganda

Supplying premium quality Pipe wrapping tape in Uganda at manufacturer price, available for delivery across Kampala, Entebbe, Gulu, Mbarara, Jinja, Mbale, Lira, Arua, Masaka, Fort Portal.

Pipe wrapping tape Supplier in Algeria

We are a wholesale supplier of Pipe wrapping tape in Algeria at manufacturer price, available for delivery across Algiers, Oran, Constantine, Annaba, Blida, Batna, Djelfa, Sétif, Tizi Ouzou, Béjaïa.

Pipe wrapping tape Supplier in Morocco

Supplying premium quality Pipe wrapping tape in Morocco at manufacturer price, available for delivery across Casablanca, Rabat, Marrakech, Fes, Tangier, Agadir, Meknes, Oujda, Kenitra, Tetouan.

Looking for Pipe wrapping tape manufacturer

in Middle East & African Countries?

Related products

<h3>Related Products</h3>

-

Sale!

Rockwool

77.00 USD – 85.00 USD This product has multiple variants. The options may be chosen on the product page -

Metal Waterstopper

7.08 USD -

Damp Proof Course

4.08 USD – 6.67 USD This product has multiple variants. The options may be chosen on the product page -

Bituminous protection board

3.00 USD